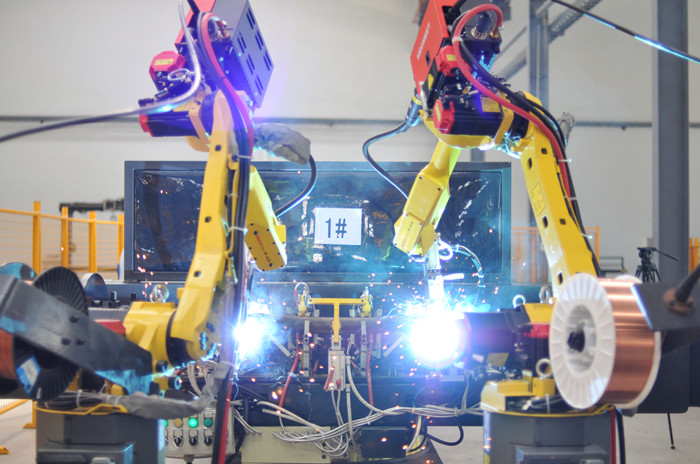

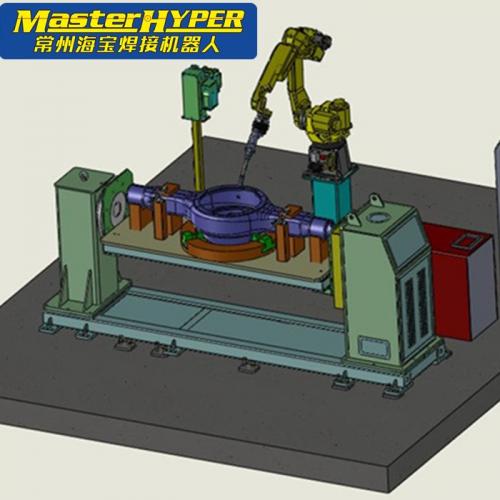

Cover beam steel frame welding robot

已阅读 3257 次09/30/2019Cover beam steel frame welding robot:

Before the advent of the cover beam rebar skeleton welding robot manipulator, with the continuous advancement of China's industrialization and urbanization process, the quality of the labor force has gradually improved, and the continuous increase of the wage level of workers has become an inevitable trend, which has long been a construction enterprise that relies on the demographic dividend. With the large cost pressure, the wages of steel workers continue to rise, making it a certain trend to replace the traditional manual processing and semi-automatic processing of steel bars with CNC steel processing equipment.

The hand-held teaching system for welding robots independently developed by our company: simple operation and powerful functions. Cover beam steel frame welding robot installation conditions:

1. The site is leveled and hardened by more than 20cm, and indoors are protected from rain.

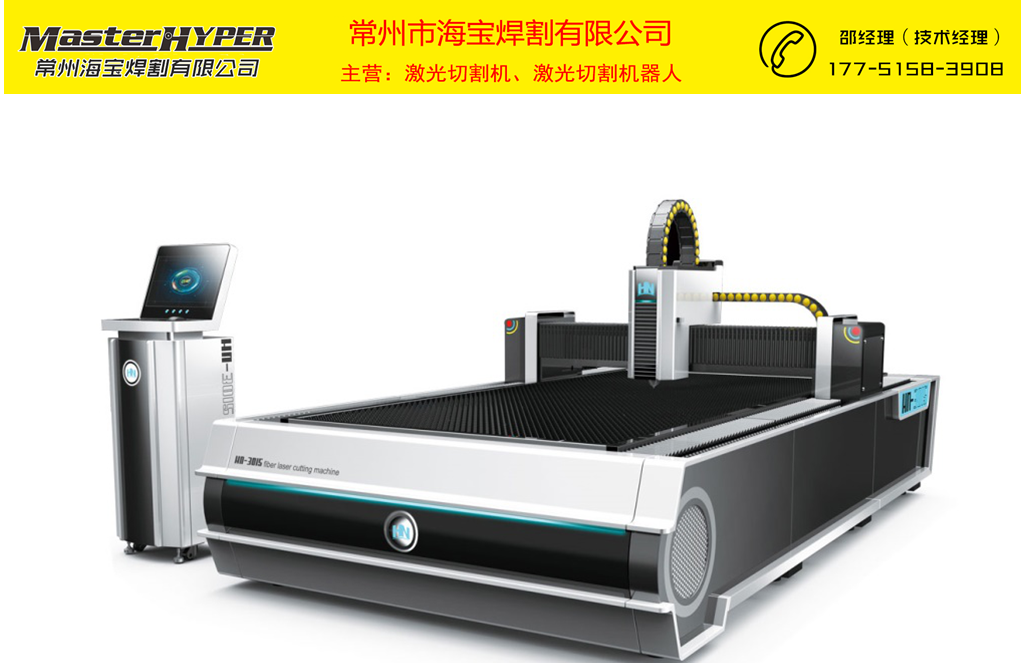

2, Changzhou Haibao on the requirements: 380V, 50Hz, power: 30KW (including welding machine).

Automatic welding processing process of cover beam steel skeleton robot: 1. Split into steel bar pattern according to design drawings; 2. Form each steel bar shape with CNC steel bar bending; 3. Fix bending formed steel bars to 1# and 2# stereotypes On the template. 4. Start the welding robot to weld the 1# and 2# skeletons. At the same time, the welded steel bars are fixed to the 3# and 4# stencils; the machine does not stop and the cycle is welded.

查看所有评论(总共0条)评论列表